Endless Custom Power Supply Options

Thirty years of industry experience , ETA-USA has seen a plethora of unique requirements that is has engineered and can build upon to provide its customers solutions as specialized as their applications.

All of of products are TAA compliant. Rackmount, Military, Avionics, and IP65+ Rated products are made in the USA. CAD and STEP models available upon request.

Contact an ETA-USA Representative for Details

Customized AC/DC External Adapters, TAA Compliant.

ETA-USA’s ITE and medical grade external power adapters can be customized to power your application requirements with low minimum order quantities and 1-2 piece evaluation units available to purchase.

- 25W~400W ITE and Medical Grade Products

- Single and Multiple Outputs

- Customizable AC Inlets (select Models) DC out connector and Cables.

- DOE VI and DOE VI Compliance

- TAA Compliant

- IP42

- Customer Name and Part Number Can Be Added at no Additional Charge

- UL, UK, CE, & TUV Safety Certified

- US, UK, EU, & JP AC Cords Can be Ordered & Packaged with Product

Rackmount AC/DC & DC/DC Power Systems Made in the USA

ETA-USA designed and built its first Rackmount for Alstom MUX Train Control system in 1998, which have been in use and operating for over 25 years without requiring service. ETA-USA can quickly deliver a robust and reliable rackmount power systems in as little as 8 weeks after order.

- 19 Inch Rackmount Units at 1U, 2U, 3U, and 4U sizes

- Up to 8 Separate & Isolated Outputs or 4 Outputs with Redundancy

- LED Display with Voltage & Current Reading

- Alarm Signals & Power Good Indicator

- I2C Reporting Options Available

- Industrial & Military Grade Options Available

- DC/DC Models Available

Military & Defense

ETA-USA is ITAR registered and all of its Mil-grade and Defense compliant power supplies are designed and built in the USA. ETA-USA maintains an NIST SP800 compliant

- Conduction Cooled Single Output AC/DC Power Supplies form 500~2,000W, 50/60/400Hz Input Frequency

- Convection Cooled Single and Multiple Output AC/DC Power Systems up to 6,000W

- Single and 3 Phase Options

- Convection and Conduction Cooled DC/DC Models, Meets Mil-Std 1279

- Mil-Std 461. 810, & 1399 compliant. Mil-Std 910 enclosure Designs Available.

- User Selectable D38999 or 5015 Connectors available.

- Multiple, Isolated Output Voltages Available.

- Anodized, Chromate, or Powder Coat finishes

- Low MOQ

- High Altitude Models Coming Soon

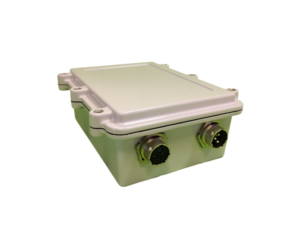

Semi-Custom Outdoor and Ingress Protection

ETA-USA can package its designs into an IP65+ Rated enclosure to be used in rugged and outdoor environments.

- Selection of Proven designs for AC/DC & DC/DC requirements form 300~1,400W

- Heatsink Design Capability for High Wattage, Environmentally Sealed

- IECeX for Explosive Environment Model Line Available

- View Semi-Custom Page for Baseline Models

Custom Design Capabilities

- Rapid Design to Prototype Cycle

- Non-Standard Input & Output Voltages, Isolation Voltages

- Low and High Volume manufacturing

- CAD models available

- EMI & Temperature Testing

- Engineering experience to meet Commercial, Industrial, Military, and Aviation standards

- ISO 9001 2015 Certified, AS9100 Compliant

- Engineering and Technical Support to Obtain 3rd Party Certification